SAGE THERMAL SHIELD® PREVENTS ALL COMMON CAUSES OF LEAKS IN PANELS

LEAK PROOF EAF PANELS

Sage Panels are protected against the three mains causes of leaks, which have been considered unavoidable for longer than a century.

Thermal Cracks

Tubes forming the panels in an EAF have their outer wall exposed to extremely high temperatures while inner wall remains cooled by water flow.

Every time power is turned off, huge temperature differences between inner and outer tube walls induce thermal cracks as shown at right.

No sudden cooling/heating Occurs in sage panels.

Chemical Attack

Oxidizing atmospheres and high temperatures cause severe wear to the tubes material. During the primary refining, the environment between liquid bath, roof and shell tubes shifts from oxidizing to reducing atmospheres.

Both conditions impose corrosion on the walls causing leaks as shown at right.

Electric Arc Discharge

Due to the own nature of the process this type of failure has been considered since 2009 when Electric Arc Furnaces began to operate.

SAGE THERMAL SHIELD®

Typically, the thermal shield is restored once a year for most applications.

They are put back into operation in their “as new” condition.

Maintenance is included throughout the duration of the lease agreement chosen by users.

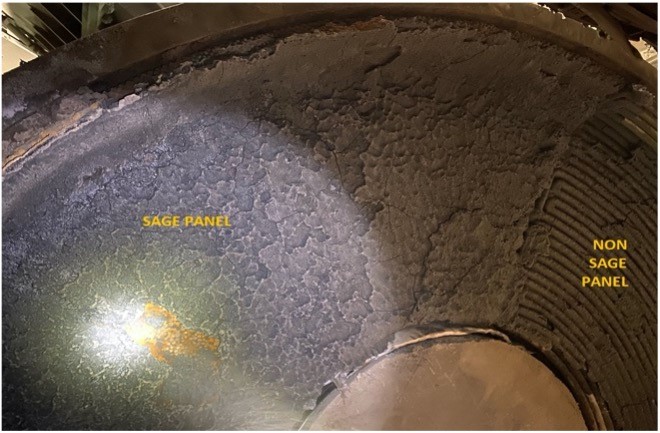

INSULATION STABILITY

Sage Panels are designed either to maximize retention of heat inside the furnace or to absorb heat from panels beyond the furnace.

At right one can see the optimized insulation with no exposure to direct radiation.

DIRECT TEMPERATURE MEASUREMENT AT PANEL HOT FACE

Sage panels are the only ones in the industry, capable to have temperatures at the hot face of panels measured and recorded in real time.

Thermocouples are inserted under a permanent layer of refractory in direct contact with the tube metal reducing water needs to less than 50%.

Radical reduction of carbon emissions that soon will be globally taxed

TEMPERATURES MEASURED, STORED AND ANALYZED FOR FLOW OPTIMIZATION

EXAMPLES OF APPLICATIONS